R&D Department

Main tasks of R&D Department are improving technologies, materials, products and technician's skills in order to meet all markets needs and all our customers' requirements.

SEA R&D Department is branched in 2 different areas:

- Liquid immersed products:

transformers, reactors and special products

- Dry type products:

transformers, reactors and special products

Each area is able to manage 2D and 3D modelling or parametric software for mechanical design, electrical calculation tools and auxiliary circuits diagram: the most modern software applications are used and continuously improved.

A complete set of electrical, mechanical and hydraulic softwares mixed with our designers' experience assures the possibility to calculate and design every type of complication in transformer industry.

Reliability, the basic word in the field of energy

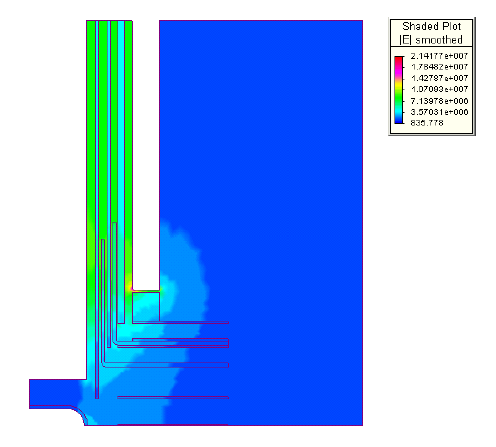

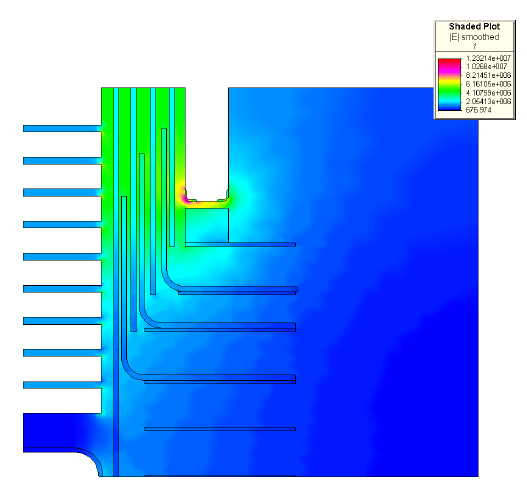

Finite Element Method can be used both for electromechanical, thermal and mechanical analysis.

This way let us to verify in an accurate way the performance of electric and thermal structural parts in order to keep under control the most critical areas of the transformer.

Thank to this method some improvements can be performed to the insulation design of HV regulating winding midsection, for example analysing the electric field strength.

Max field stress tap winding and stress in the oil duct can be significantly reduced, as well as the formation of partial discharges.

Electric field strenght at the first analysis (left side) and after the corrections (right side)

Our engineers and technicians are focused also to develop new and innovative products, improving reliability first.